I-Sintered Silicon Carbide Micropowder Green

Imininingwane yomkhiqizo:

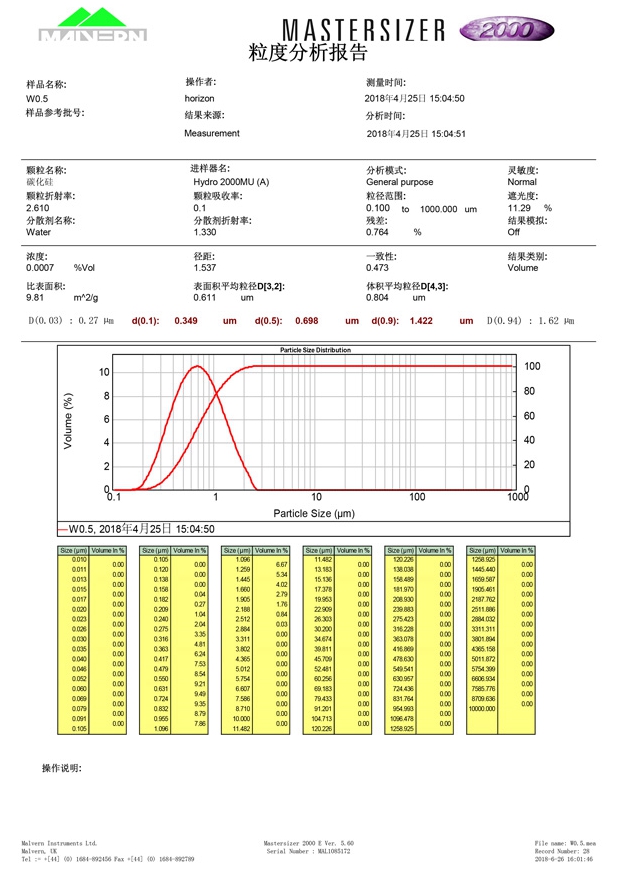

I-1.Micropowder GC0.5 yenziwe nge-high pureity silicon carbide material eluhlaza enekhwalithi enhle, Ithuthukiswe ngendlela ehlanganisiwe

I-2.GC0.5 i-powder encane inenzuzo ehlukile njengokusatshalaliswa kosayizi wezinhlayiyana ezincane, uketshezi oluhle, ukuncipha kokushisa okuphansi nobukhulu obukhulu bokukhotha, njll.

Okuqukethwe kwe-Oxygen kwale micropowder kulawulwa ngempumelelo ngokusebenzisa ubuchwepheshe obukhethekile bokushisa nobuchwepheshe bokomisa

Isicelo:

Le micropowder ithengisa kahle eJapane nasezimakethe zaseYurophu futhi isetshenziswa kakhulu ku-mechanical seal, armorsproof armors, chemical and petroleum and aerospace area, Heat Exchanger Tubes, Blast and Atomization Nozzles, Process Industry Industry Valve Applications, Paper Industry Applications, Centrifuge Tiles and Gqoka Izingxenye, Ukukhiqizwa Kwe-Semiconductor, njll

Okuqukethwe Kwamakhemikhali:

|

Imodeli |

I-SiC |

I-Fe2O3 |

FC |

SiO2 |

PH |

Okuqukethwe kwamanzi |

|

W0.5 |

98.90% |

0.01% |

0.15% |

0.18% |

7 |

0.02% |

Ukupakisha: 25Kg / 50kg isikhwama sePlastiki noma ngezifiso njengamaklayenti

Isikhathi sokuthumela: 1 * 20GP isitsha sithatha cishe izinsuku eziyi-7 kuya kwezingu-10

MOQ: 1Thon

Amasampula: Uma iKhasimende lidingeka, amasampula wamahhala ayatholakala futhi akhokhisa ukuthunyelwa

Inqubo Yokukhiqiza:

I-Sintered silicon carbide (i-SiC) ikhiqizwa ngokuxuba okokuqala i-fine (sub-micron) kanye ne-pure silicon carbide powder nezinsiza ezingeyona i-oxide sintering. Izinto eziyimpuphu zenziwa noma zihlanganiswe ngokusebenzisa iningi lezinqubo ezijwayelekile zokwakha i-ceramic ezifana nokucindezela u-die, ukucindezela kwe-isostatic nokujova ngomjovo. Ukulandela isigaba sokwakha okokusebenza kufakwa endaweni engenamazinga okushisa angaphezu kuka-2000 ° C. I-sintered silicon carbide ingahle isetshenziselwe ukucacisa kahle ukubekezelelana kusetshenziswa izindlela ezahlukahlukene zokugaya noma zokuxegisa idayimane.

Izakhiwo eziyisihlakala ze-silicon carbide

Ubulukhuni 1.High (yesibili kuphela idayimane)

2.Low kwabantu 40% kwabantu insimbi - cishe efanayo aluminium

Porosity 3.Low

4.Good bafake ukumelana ezindaweni beya futhi olwalwenza

5.Excellent ukugqwala ukumelana ezindaweni eziningi zamakhemikhali

Ukunwetshwa okuphansi kwe-6.Low nokushisa okuphezulu okushisayo okuholela ekumelaneni okuhle kakhulu kokushisa.

Inqubo Yokubambisana yamakhasimende amasha

1.Ukuxhumana namakhasimende nge-imeyili nangocingo bazi kahle ngomkhakha wemboni yamakhasimende kanye nemfuneko ku-Silicon Carbide parameter.

2.Sinikeza amakhasimende isiphakamiso esihle nesinengqondo kumodeli yomkhiqizo.

3.Its iyatholakala ukuthumela amasampuli noma ukulethwa ngeqoqo elincane ekubhekeni ikhwalithi

Ngemuva kokuqinisekiswa kwamakhasimende, landela lokhu njengokujwayelekile bese uya ekukhiqizeni, gcina amasampula athile ukuze izinhlangothi zombili zihlole ngokuzayo.